Marsh Fasteners has a wide range of stainless steel eye bolts and hooks that are perfect for all kinds of uses. These sturdy products can handle heavy tasks in industrial work and do-it-yourself projects. We make sure to meet the best quality standards when manufacturing these items so they last long and work reliably. If you are handling a big construction job or doing some home fixings, our stainless steel fasteners offer the toughness and protection from rust needed for success with your task.

Why Choose Stainless Steel Bolts?

Stainless steel bolts have many benefits compared to other materials, which make them very suitable for different uses. This is particularly true in places that are outside or near the coast. Here are some of their main advantages:

- Resistance to Corrosion: Stainless steel, especially types 316 and 18/8, is very good at resisting corrosion and rust. This quality makes it an excellent choice for items that are exposed to moisture and salt water.

- Strength and Endurance: Stainless steel fasteners are strong and durable, making them suitable for enduring challenging situations. They also show excellent resistance to corrosion, which means they can withstand harsh environments without weakening or breaking down over time. This quality makes stainless steel an ideal choice for outdoor applications or places where moisture is present frequently, such as kitchens and bathrooms.

- Low Upkeep: They need less maintenance, saving time and money in the long run.

- Aesthetic Pleasure: Stainless steel keeps looking good with use, giving a neat and formal feel.

- Environmental Benefits: Stainless steel is 100% recyclable, making it an environmentally friendly choice.

Applications for Stainless Steel Bolts

Bolts and hooks made from stainless steel are flexible in use, and suitable for various applications, including the following:

- Lifting and Rigging: Stainless steel eye bolts are a frequent choice in lifting and rigging jobs because they are tough and dependable. They offer safe securement spots for hoisting tools and substances.

- Anchoring: Eye bolts are used for fastening buildings and items inside and outside. Their ability to withstand corrosion makes them an excellent choice for permanent placements in severe surroundings.

- Marine Applications: Eye bolts made from stainless steel are ideal for boats, docks, and other marine environments where resistance to corrosion is important. They guarantee safety and durability in these tough surroundings.

- Industrial Applications: This includes using them in machines and tools to hold or direct cables or ropes. Due to their toughness and strength, they are chosen because they can handle heavy-duty work.

- Construction: Frequently used in multiple construction projects to secure things temporarily or permanently. Stainless steel eye bolts offer dependable fastening answers for all building types, including residential and commercial constructions.

Key Features

Here are some of the key features of stainless steel bolts:

- High Tensile Strength: Stainless steel eye bolts and hooks provide excellent tensile strength, ensuring that they can bear substantial loads and strains. They are perfect for robust uses where dependability is vital.

- Corrosion Resistance: Being made of stainless steel means they do not rust or get damaged by the environment. This quality makes these fasteners a good choice in tough situations like those on the coast and in marine settings.

- Easy Installation: Stainless steel fasteners are simple to set up. They work well with standard tools and allow for swift, solid assembly. This guarantees that your work gets finished quickly and correctly without compromising quality.

- Accurate Threading: With their careful threading, the stainless steel eye bolts and hooks ensure a snug fit that won’t become loose. This is especially important for keeping your setups secure and safe from wear.

Explore Our Range of Stainless Steel Eye Bolts and Hooks

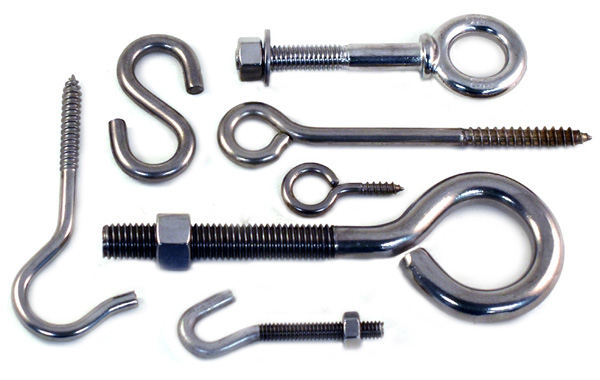

At Marsh Fasteners, we have many types of stainless steel eye bolts and hooks, including the following:

Stainless Steel Eye Bolts

- Stainless Steel Shoulder Eye Bolts: Designed for angular loads, providing extra strength and durability. Shop stainless steel shoulder eye bolts.

- Machinery Eye Bolts: Ideal for heavy-duty lifting and securing machinery. Shop machinery eye bolts.

- Stainless Steel Lag Thread Eye Bolts: Perfect for screwing into wood or other materials. Shop stainless steel lag thread eye bolts.

- Stainless Steel Threaded Eye Bolts with Nut: Deliver secure fastening, having additional stability due to the nut’s presence. Shop stainless steel threaded eye bolts with nut.

Stainless Steel Hooks

- Stainless Steel Screw Eyes: Versatile and durable for various applications. Shop stainless steel screw eyes.

- Stainless Steel Screw Hooks: Ideal for secure and reliable fastening. Shop stainless steel hooks.

- Stainless Hitching Ring Bolts: Perfect for hitching and securing loads. Shop stainless steel hitching ring bolts.

- Stainless Steel S Hooks: Great for hanging and securing items with ease. Shop stainless steel S hooks.

What Our Customers Say

Order Your Stainless Steel Eye Bolts and Hooks or Request a Quote

Want to start working on your next task? Look through the variety of stainless steel bolts we have and make an order now. Have a pleasant experience with quick delivery as well as top-class customer support from Marsh Fasteners.

Related Products You Might Also Like

- Stainless Steel Nuts: Essential for securing bolts and ensuring a strong, reliable connection.

- Stainless Steel Washers: They give a stable surface for spreading the load and preventing harm to surfaces.

- Threaded Rods: Versatile fasteners used in a variety of construction and repair applications.

- Stainless Steel Screws: Perfect for a variety of uses, they are highly resistant to corrosion and have good strength.

- Stainless Steel Bolts: High-quality fasteners for reliable and durable connections.

FAQs

Here are some of the FAQs we get about stainless steel eye bolts and hooks:

What kinds of hooks in stainless steel are there, and how should I select the correct one?

These are the types available:

- S-Hooks: Shaped like an “S,” used for hanging and securing light to medium loads.

- Snap Hooks: These have a gate with a spring mechanism which can be opened and closed for fast and safe connections.

- Carabiner Hooks: These are like snap hooks, but they tend to be utilized in climbing and other pursuits that need superior strength.

- J-Hooks: Shaped like a “J,” used for hanging items securely.

- Eye Hooks: Have a looped end for attaching ropes or cables securely.

Choosing the Right Hook:

- Load Capacity: Select based on the weight and load requirements of the application.

- Type of Load: Consider the type of load and how it attaches to the hook. Then choose between open hooks, snap hooks or eye hooks.

- Conditions of the Environment: Make sure the hook is compatible with environmental conditions, especially if it will be utilized in corrosiveness or marine environments..

- Size and Strength: Ensure the hook is appropriately sized and strong enough for the application.

How do I ensure the secure installation and use of stainless steel hooks?

Follow these steps to ensure a secure installation:

- Anchor Points: Make sure the hooks are connected to strong and steady anchor points that have the ability to hold up the load.

- Correct Tools: Use appropriate tools for installing hooks to ensure. they are securely fastened.

- Load Alignment: Make sure the hook is in line with the load’s direction, so no bending or deformity happens.

- Standard Examinations: Check the condition of hooks often, looking for indications of wear, rusting or harm. Put in new ones when needed.

Follow these steps to ensure it is used safely and securely:

- Load Limits: Do not exceed the load capacity of the hook.

- Even Distribution: Distribute the load evenly to prevent stress concentration on a single point.

- Safety Measures: Keep to safety rules for lifting and fastening loads, notably in industrial and building areas.

What are the varieties in stainless steel eye bolts, and how can I make a selection?

These are the types of stainless steel eye bolts:

- Standard Eye Bolts: Have a simple looped head, suitable for general purposes.

- Shoulder eye bolts: They have a shoulder located under the eye, which can bear angular loads and offer more strength.

- Lag Eye Bolts: Have a threaded end for screwing into wood or other materials.

- Machinery Eye Bolts: Designed for heavy-duty lifting and securing machinery.

Choosing the Right Eye Bolt:

- Load Capacity: Select based on the weight and load requirements of the application.

- Type and Length: Make sure the type of thread is appropriate for the material you are going to secure it in, and also consider if it is long enough to ensure a strong hold.

- Head Type: Select from standard or shoulder eye bolts, this depends on whether there is a requirement for handling angular load.

- Environmental Conditions: Check if the eye bolt is appropriate for environmental conditions, particularly when it’s used in areas with corrosion or marine elements.

How do I correctly install stainless steel eye bolts to ensure safety and reliability?

Follow these steps for the proper installation:

- Pre-Drill Holes: For lag eye bolts, pre-drill holes of appropriate size for a snug fit.

- Utilize Washers and Nuts: When using eye bolts that have through holes, apply washers and nuts to fix them. This helps in spreading the load evenly and stops pull-through.

- Torque Specifications: Fasten the eye bolts with torque specifications for a steady and dependable hold.

- Check Alignment: Verify that the eye bolt is aligned with the load to prevent side loading, which may decrease its load-carrying capacity and lead to failure.

- Routine Inspections: Perform regular checks on eye bolts to identify any wear, corrosion, or impairment that may have occurred and replace them when necessary.

Contact Marsh Fasteners for fast shipping, great customer service, and the best selection of stainless steel fasteners for coastal construction and fastening.